Kde nás najdete?

Z bezpečnostních důvodů jste byli odhlášeni.

Find products by either scanning QR code or EAN code

Unable to detect / invalid code

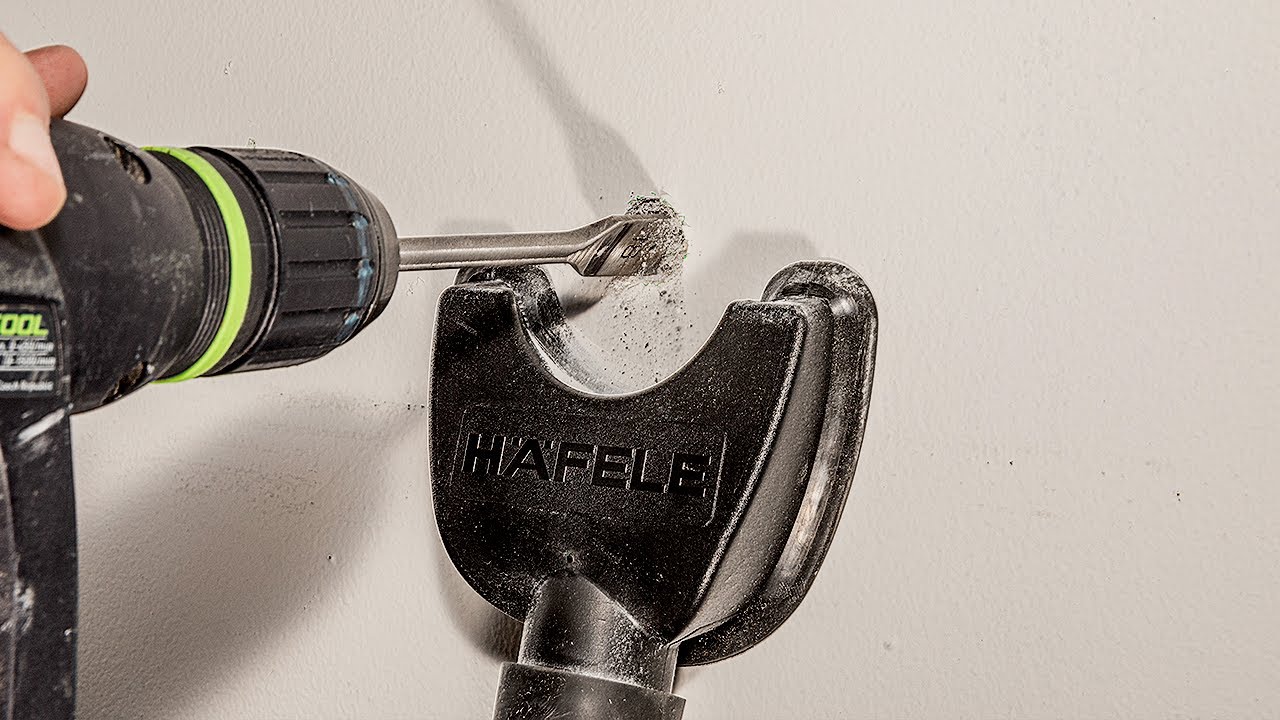

Häfele XtraHand pro snadné a čisté vrtání na většině povrchů. Objednací číslo 008.53.620.

Prostřednictvím konfigurátoru můžete snadno a rychle objednat LED svítidlo na míru

Vybraný sortiment Häfele pro kompletní vybavení kuchyně z jednoho zdroje

NÁPADY V POHYBU.

Inovativní zástěna pracovní desky

S revolučním výklopem nastavujeme nové standardy.

Ať jste učeň, středoškolák, vysokoškolák nebo specialista – Häfele neustále hledá kvalifikované zaměstnance po celém světě. Vyhledejte volná pracovní místa, pošlete online poptávku a přidejte se do světa Häfele.

V sekci Tisk najdete nejnovější tiskové zprávy, správné kontaktní informace pro novináře a přehled všech aktivit společnosti.

Häfele je mezinárodní společnost nabízející systémy stavebního a nábytkového kování a elektronické systémy řízení vstupu. Zákazníci po celém světě z nábytkového průmyslu, prodejci, truhláři, konstruktéři, architekti, projektanti a stavitelé - ti všichni spoléhají na odbornost a produkty společnosti Häfele.